Pre-Engineered Buildings (PEB) have transformed the way industrial and commercial structures are designed and constructed. The PEB full form is Pre-Engineered Buildings, which refers to steel structures that are factory-fabricated and assembled at the project site.

In today’s fast-growing industrial landscape, businesses prefer PEB construction due to its speed, cost efficiency, durability, and design flexibility. From warehouses and factories to logistics parks and showrooms, PEB buildings are widely used across India.

What Is the Full Form of PEB?

The full form of PEB is Pre-Engineered Buildings.

These are steel building systems designed, engineered, and manufactured in a factory environment before being transported to the construction site for installation.

Unlike traditional RCC construction, PEB structures are pre-planned and precision-built, ensuring faster completion and minimal material wastage.

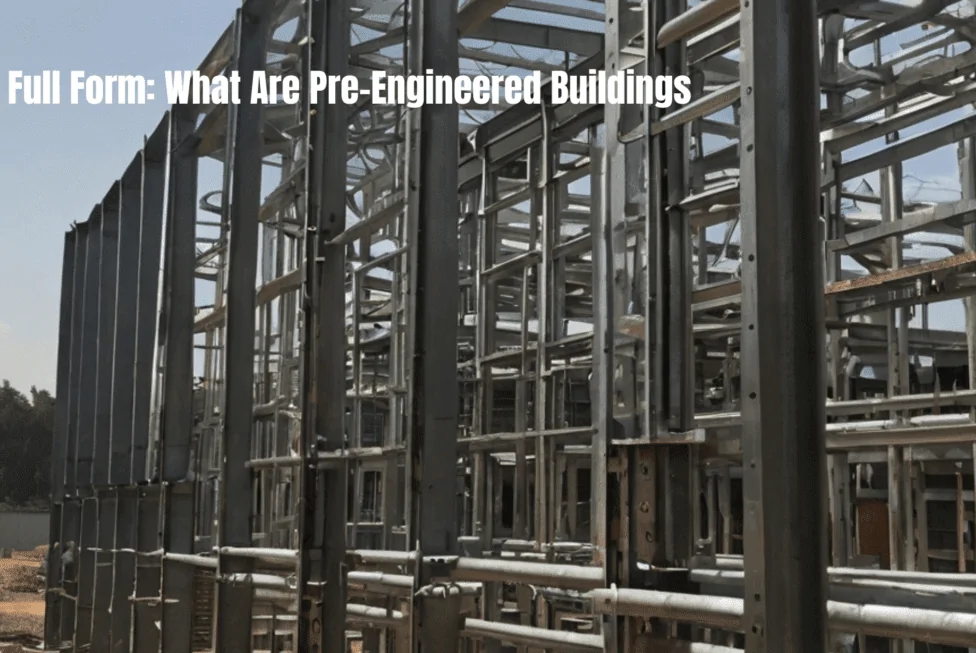

What Are Pre-Engineered Buildings?

Pre-Engineered Buildings are modern steel structures made using built-up sections, hot-rolled components, and cold-formed elements.

They are designed using advanced engineering software based on:

Load requirements

Soil conditions

Building usage

Climate factors

Span & height requirements

Once designed, components are manufactured in a factory and assembled on-site using bolted connections.

This process reduces construction time significantly compared to conventional buildings.

Components of PEB Structure

A PEB building consists of multiple engineered components that work together to provide strength and durability.

1️⃣ Primary Frame

Columns

Rafters

Built-up steel sections

These form the main load-bearing structure.

2️⃣ Secondary Members

Purlins

Girts

Eave struts

They support roofing and wall sheets.

3️⃣ Roofing & Cladding

Color coated sheets

Galvalume sheets

Insulated panels

They protect from weather and improve insulation.

4️⃣ Bracing System

Provides structural stability against wind and seismic loads.

5️⃣ Accessories

Skylights

Turbo ventilators

Ridge ventilators

Gutters & downpipes

Benefits of PEB Buildings

1️⃣ Faster Construction

PEB projects complete 30–50% faster than traditional construction because components are pre-fabricated.

2️⃣ Cost Efficient

Lower material wastage + reduced labor = lower overall project cost.

Average cost in India:

₹180 – ₹350 per sq ft (depends on specs).

3️⃣ Large Clear Span

PEB structures can achieve wide column-free spaces, ideal for warehouses & factories.

4️⃣ Design Flexibility

Easy to customize height, width, crane provision, mezzanine floors, etc.

5️⃣ Durable & Low Maintenance

Steel structures resist termites, cracks, and structural decay.

6️⃣ Expandable Structure

Future expansion is easy without major demolition.

Applications & Industries Using PEB

Pre-Engineered Buildings are used across multiple industries:

🏭 Manufacturing Units

Ideal for machinery installation and production lines.

📦 Warehouses & Logistics Parks

Large clear spans improve storage efficiency.

❄️ Cold Storage Facilities

Insulated panels maintain temperature control.

🛒 Commercial Showrooms

Attractive facades with glass & ACP cladding.

🚚 Transport & Distribution Centers

Optimized for truck movement & loading bays.

🏢 Industrial Sheds

Used in MIDC & industrial zones.

PEB vs Traditional Construction

| Factor | PEB Buildings | RCC Buildings |

|---|---|---|

| Construction Time | Fast | Slow |

| Cost | Lower | Higher |

| Span Width | Large clear span | Limited |

| Expansion | Easy | Difficult |

| Maintenance | Low | Moderate |

| Material Waste | Minimal | High |

Cost of Pre-Engineered Buildings in India

PEB building cost depends on multiple factors:

Building size & height

Load capacity

Crane provision

Roofing insulation

Wind & seismic zone

Material grade

Average Price Range:

| Structure Type | Cost Per Sq Ft |

|---|---|

| Industrial Shed | ₹180 – ₹250 |

| Warehouse Building | ₹200 – ₹300 |

| Factory Shed | ₹220 – ₹350 |

Note: Prices vary based on project specifications.

Why Choose PEB Utkarsha?

If you are planning a PEB project in Nagpur or MIDC areas, PEB Utkarsha offers end-to-end solutions.

Our Key Strengths:

10+ Years Industry Experience

Modern Fabrication Facility

In-House Design Team

Turnkey Project Execution

Skilled Erection Crew

Quality Steel Standards

On-Time Delivery

We specialize in industrial sheds, warehouses, factory buildings, and custom PEB structures.

Our PEB Solutions Include

Industrial Shed Construction

Warehouse PEB Buildings

Factory Structures

Steel Building Fabrication

Turnkey PEB Projects

Mezzanine Floor Systems

All structures are engineered for strength, scalability, and long service life.

Get a Free Quote for Your PEB Project

Planning to build a warehouse or industrial shed?

📞 Call Now for Project Consultation : +91 96657 02330

📩 Request Free Design & Cost Estimate : https://pebutkarsha.co.in/contact-pebutkarsha/

📍 Site Visit Available Across Nagpur & MIDC Areas : BOOK NOW

Our experts will guide you from concept to completion.

Conclusion

Understanding the **PEB full form—Pre-Engineered Buildings—**is essential for businesses planning modern industrial infrastructure.

With benefits like faster construction, lower costs, durability, and expansion flexibility, PEB structures have become the preferred choice for warehouses, factories, and commercial facilities.

As industrial demand grows, PEB technology will continue to shape the future of smart construction in India.

Frequently Asked Questions (FAQs)

Q1. What is the full form of PEB?

PEB stands for Pre-Engineered Buildings, which are factory-fabricated steel structures assembled on-site.

Q2. What are PEB buildings used for?

They are used for warehouses, factories, cold storage, showrooms, and logistics parks.

Q3. What is the cost of PEB buildings in India?

The average cost ranges from ₹180 to ₹350 per sq ft depending on design and materials.

Q4. Is PEB construction faster than RCC?

Yes, PEB buildings reduce construction time by up to 50%.

Q5. How long do PEB buildings last?

With proper maintenance, they can last 25–50 years or more.